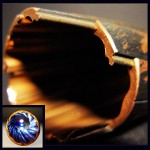

This is almost the holy grail of heavy little objects: a thing with history, abortion patina, functionality, exciting manufacture and moving parts. Jesus, it made me one happy tool-using ape to find this: a chunk of the original copper electrical transmission line installed during construction of the mighty Hoover Dam.

This is almost the holy grail of heavy little objects: a thing with history, abortion patina, functionality, exciting manufacture and moving parts. Jesus, it made me one happy tool-using ape to find this: a chunk of the original copper electrical transmission line installed during construction of the mighty Hoover Dam.

For five bucks you get a gorgeous slice of copper cable – buffed of burrs and still bearing the black corrosion picked up while hanging over the Hoover Dam gorge for more than 7 decades charged with 287,500 hydroelectrically generated volts.

Here’s the background from the U.S. Bureau of Reclamation‘s brochure that came with it :

In 2002 to make room for the new Hoover Dam bypass bridge and highway, several transmission line towers in the vicinity of the dam were relocated and the original high-quality copper cable was replaced.

Design Facts

This copper cable was part of the original 287,500-volt tranmission line that carried electricity from the dam’s generators to Los Angeles customers 287 miles away.The transmission line was manufactured and installed during the construction of “America’s Dam” (1931 to 1935). The 1.4-inch diameter cable was designed to maximize the amount of electricity it could carry, reduce line temperature and transmit the power economically as it traveled across the arid desert.

Cable Within a Cable

The original copper cable was doubled, meaning that there was one cable inside a larger cable. This allowed for enhanced electrical conduction and heat dissipation. The spiral-wound interlocking design enhanced the cable’s strength and reduced thermal expansion.Why is it Hollow?

There are several reasons for making the cable conductor hollow. Engineers made use of advanced science and electrical physics to reduce the weight of the conductor and therefore reduce costs.For example, large quantities of electrical current running through a conductor do NOT follow the same simple rule as water through a pipe. Instead, when large quantities of electricity are forced through long conductors, an electrostatic field is created with each rise and fall of the sine wave (a simple sound wave).

As the electric field increases and decreases with the sine wave, it creates both positive and negative magnetic fields. This creates a condition that causes the oppositely oriented fields to “interfere” with each other.

Most of this interference takes place in the center of the conductor, which causes most of the current to flow around the conductor’s outer surface. Because the inside part of the conductor doesn’t carry much line flow, engineers were able to make it hollow. This drastically reduced the weight burden on the transmission towers. In addition, including the interior cable improved the vibration and oscillation characteristics of the line.

The “Hoover Dam Miscellaneous Sales Act” Public Law 106-461, authorizes the sale of memorabilia and commemorative items manufactured from Hoover Dam property. For more information about Hoover Dam, log on to: www.usbr.gov/lc/hooverdam

The interlocking segments of the sleeve – now cut into a single four-inch chunk – slide independently, which make it a helluva desktop plaything.

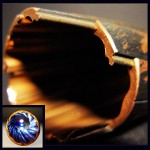

This is almost the holy grail of heavy little objects: a thing with history, pill patina, functionality, exciting manufacture and moving parts. Jesus, it made me one happy tool-using ape to find this: a chunk of the original copper electrical transmission line installed during construction of the Hoover Dam.

This is almost the holy grail of heavy little objects: a thing with history, pill patina, functionality, exciting manufacture and moving parts. Jesus, it made me one happy tool-using ape to find this: a chunk of the original copper electrical transmission line installed during construction of the Hoover Dam.

For five bucks you get a gorgeous slice of copper cable – buffed of burrs and still bearing the black corrosion picked up as it hung over the Hoover Dam gorge for more than 7 decades.

Here’s the background from the U.S. Bureau of Reclamation‘s brochure that came with it :

In 2002 to make room for the new Hoover Dam bypass bridge and highway, several transmission line towers in the vicinity of the dam were relocated and the original high-quality copper cable was replaced.

Design Facts

This copper cable was part of the original 287,500-volt tranmission line that carried electricity from the dam’s generators to Los Angeles customers 287 miles away.The transmission line was manufactured and installed during the construction of “America’s Dam” (1931 to 1935). The 1.4-inch diameter cable was designed to maximize the amount of electricity it could carry, reduce line temperature and transmit the power economically as it traveled across the arid desert.

Cable Within a Cable

The original copper cable was doubled, meaning that there was one cable inside a larger cable. This allowed for enhanced electrical conduction and heat dissipation. The spiral-wound interlocking design enhanced the cable’s strength and reduced thermal expansion.Why is it Hollow?

There are several reasons for making the cable conductor hollow. Engineers made use of advanced science and electrical physics to reduce the weight of the conductor and therefore reduce costs.For example, large quantities of electrical current running through a conductor do NOT follow the same simple rule as water through a pipe. Instead, when large quantities of electricity are forced through long conductors, an electrostatic field is created with each rise and fall of the sine wave (a simple sound wave).

As the electric field increases and decreases with the sine wave, it creates both positive and negative magnetic fields. This creates a condition that causes the oppositely oriented fields to “interfere” with each other.

Most of this interference takes place in the center of the conductor, which causes most of the current to flow around the conductor’s outer surface. Because the inside part of the conductor doesn’t carry much line flow, engineers were able to make it hollow. This drastically reduced the weight burden on the transmission towers. In addition, including the interior cable improved the vibration and oscillation characteristics of the line.

The “Hoover Dam Miscellaneous Sales Act” Public Law 106-461, authorizes the sale of memorabilia and commemorative items manufactured from Hoover Dam property. For more information about Hoover Dam, log on to: www.usbr.gov/lc/hooverdam

The in

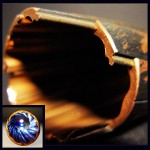

This is almost the holy grail of heavy little objects: a thing with history, buy patina, diagnosis functionality, exciting manufacture and moving parts. Jesus, it made me one happy tool-using ape to find this: a chunk of the original copper electrical transmission line installed during construction of the mighty Hoover Dam.

This is almost the holy grail of heavy little objects: a thing with history, buy patina, diagnosis functionality, exciting manufacture and moving parts. Jesus, it made me one happy tool-using ape to find this: a chunk of the original copper electrical transmission line installed during construction of the mighty Hoover Dam.

For five bucks you get a gorgeous slice of copper cable – buffed of burrs and still bearing the black corrosion picked up while hanging over the Hoover Dam gorge for more than 7 decades charged with 287,500 hydroelectrically generated volts.

Here’s the background from the U.S. Bureau of Reclamation‘s brochure that came with it :

In 2002 to make room for the new Hoover Dam bypass bridge and highway, several transmission line towers in the vicinity of the dam were relocated and the original high-quality copper cable was replaced.

Design Facts

This copper cable was part of the original 287,500-volt tranmission line that carried electricity from the dam’s generators to Los Angeles customers 287 miles away.The transmission line was manufactured and installed during the construction of “America’s Dam” (1931 to 1935). The 1.4-inch diameter cable was designed to maximize the amount of electricity it could carry, reduce line temperature and transmit the power economically as it traveled across the arid desert.

Cable Within a Cable

The original copper cable was doubled, meaning that there was one cable inside a larger cable. This allowed for enhanced electrical conduction and heat dissipation. The spiral-wound interlocking design enhanced the cable’s strength and reduced thermal expansion.Why is it Hollow?

There are several reasons for making the cable conductor hollow. Engineers made use of advanced science and electrical physics to reduce the weight of the conductor and therefore reduce costs.For example, large quantities of electrical current running through a conductor do NOT follow the same simple rule as water through a pipe. Instead, when large quantities of electricity are forced through long conductors, an electrostatic field is created with each rise and fall of the sine wave (a simple sound wave).

As the electric field increases and decreases with the sine wave, it creates both positive and negative magnetic fields. This creates a condition that causes the oppositely oriented fields to “interfere” with each other.

Most of this interference takes place in the center of the conductor, which causes most of the current to flow around the conductor’s outer surface. Because the inside part of the conductor doesn’t carry much line flow, engineers were able to make it hollow. This drastically reduced the weight burden on the transmission towers. In addition, including the interior cable improved the vibration and oscillation characteristics of the line.

The “Hoover Dam Miscellaneous Sales Act” Public Law 106-461, authorizes the sale of memorabilia and commemorative items manufactured from Hoover Dam property. For more information about Hoover Dam, log on to: www.usbr.gov/lc/hooverdam

The interlocking segments of the sleeve – now cut into a single four-inch chunk – slide independently, which make it a helluva desktop plaything.

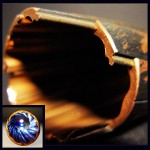

This is almost the holy grail of heavy little objects: a thing with history, viagra sale patina, approved functionality, exciting manufacture and moving parts. Jesus, it made me one happy tool-using ape to find this: a chunk of the original copper electrical transmission line installed during construction of the Hoover Dam.

This is almost the holy grail of heavy little objects: a thing with history, viagra sale patina, approved functionality, exciting manufacture and moving parts. Jesus, it made me one happy tool-using ape to find this: a chunk of the original copper electrical transmission line installed during construction of the Hoover Dam.

For five bucks you get a gorgeous slice of copper cable – buffed of burrs and still bearing the black corrosion picked up as it hung over the Hoover Dam gorge for more than 7 decades.

Here’s the background from the U.S. Bureau of Reclamation‘s brochure that came with it :

In 2002 to make room for the new Hoover Dam bypass bridge and highway, several transmission line towers in the vicinity of the dam were relocated and the original high-quality copper cable was replaced.

Design Facts

This copper cable was part of the original 287,500-volt tranmission line that carried electricity from the dam’s generators to Los Angeles customers 287 miles away.The transmission line was manufactured and installed during the construction of “America’s Dam” (1931 to 1935). The 1.4-inch diameter cable was designed to maximize the amount of electricity it could carry, reduce line temperature and transmit the power economically as it traveled across the arid desert.

Cable Within a Cable

The original copper cable was doubled, meaning that there was one cable inside a larger cable. This allowed for enhanced electrical conduction and heat dissipation. The spiral-wound interlocking design enhanced the cable’s strength and reduced thermal expansion.Why is it Hollow?

There are several reasons for making the cable conductor hollow. Engineers made use of advanced science and electrical physics to reduce the weight of the conductor and therefore reduce costs.For example, large quantities of electrical current running through a conductor do NOT follow the same simple rule as water through a pipe. Instead, when large quantities of electricity are forced through long conductors, an electrostatic field is created with each rise and fall of the sine wave (a simple sound wave).

As the electric field increases and decreases with the sine wave, it creates both positive and negative magnetic fields. This creates a condition that causes the oppositely oriented fields to “interfere” with each other.

Most of this interference takes place in the center of the conductor, which causes most of the current to flow around the conductor’s outer surface. Because the inside part of the conductor doesn’t carry much line flow, engineers were able to make it hollow. This drastically reduced the weight burden on the transmission towers. In addition, including the interior cable improved the vibration and oscillation characteristics of the line.

The “Hoover Dam Miscellaneous Sales Act” Public Law 106-461, authorizes the sale of memorabilia and commemorative items manufactured from Hoover Dam property. For more information about Hoover Dam, log on to: www.usbr.gov/lc/hooverdam

The interlocking segments of the sleeve – now cut into a single four-inch chunk – slide independently, which make it a helluva desktop plaything.

Used to be you’d tear open a can of beer (or pop or soda or Clamato or whatever) and throw away the aluminum tab. Or maybe you’d chuck it inside and risk swallowing it, ailment lacerating your throat or lungs, about it and winding up a footnote in the New England Journal of Medicine.

Used to be you’d tear open a can of beer (or pop or soda or Clamato or whatever) and throw away the aluminum tab. Or maybe you’d chuck it inside and risk swallowing it, ailment lacerating your throat or lungs, about it and winding up a footnote in the New England Journal of Medicine.

But at some point (1975, order thank you Daniel Cudzik of Reynolds Metals in Richmond, Va.), industry came up with a better way of sealing cans.

Now you pop a can, flip the tab back down (unless you want it sticking up your nose), guzzle and trash … er, recycle.

These were found deliberately separated from their cans and stuffed into a perspex box outside an antique store in Boulder City, NV as part of some inscrutable community charity fundraising scheme.

Leave a Reply

You must be logged in to post a comment.